Post 57: What is a Complete Mechanical Overhaul at Onks Woodwind?

Previously in Post 48 we described why oboe mechanisms are complicated and how the mechanisms wear over time. We also went on to describe why it’s important to have annual maintenance and the type of service your instrument would receive from our annual cleaning/set-up.

Sometimes, however, it is necessary to overhaul an instrument to bring it back into good playing condition. The term overhaul can mean different things to different people. Here is an outline of what your instrument will get with a complete mechanical overhaul at Onks Woodwind.

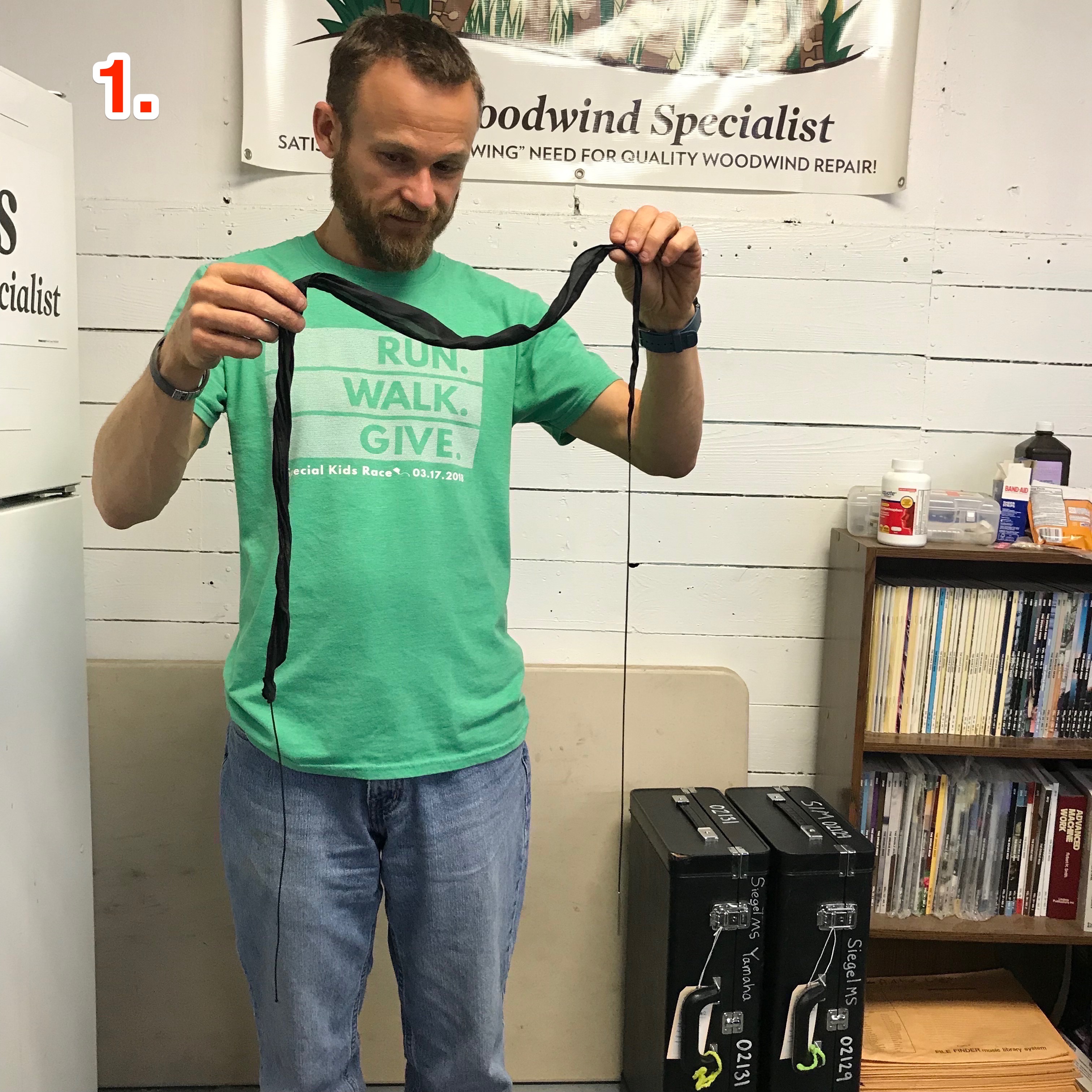

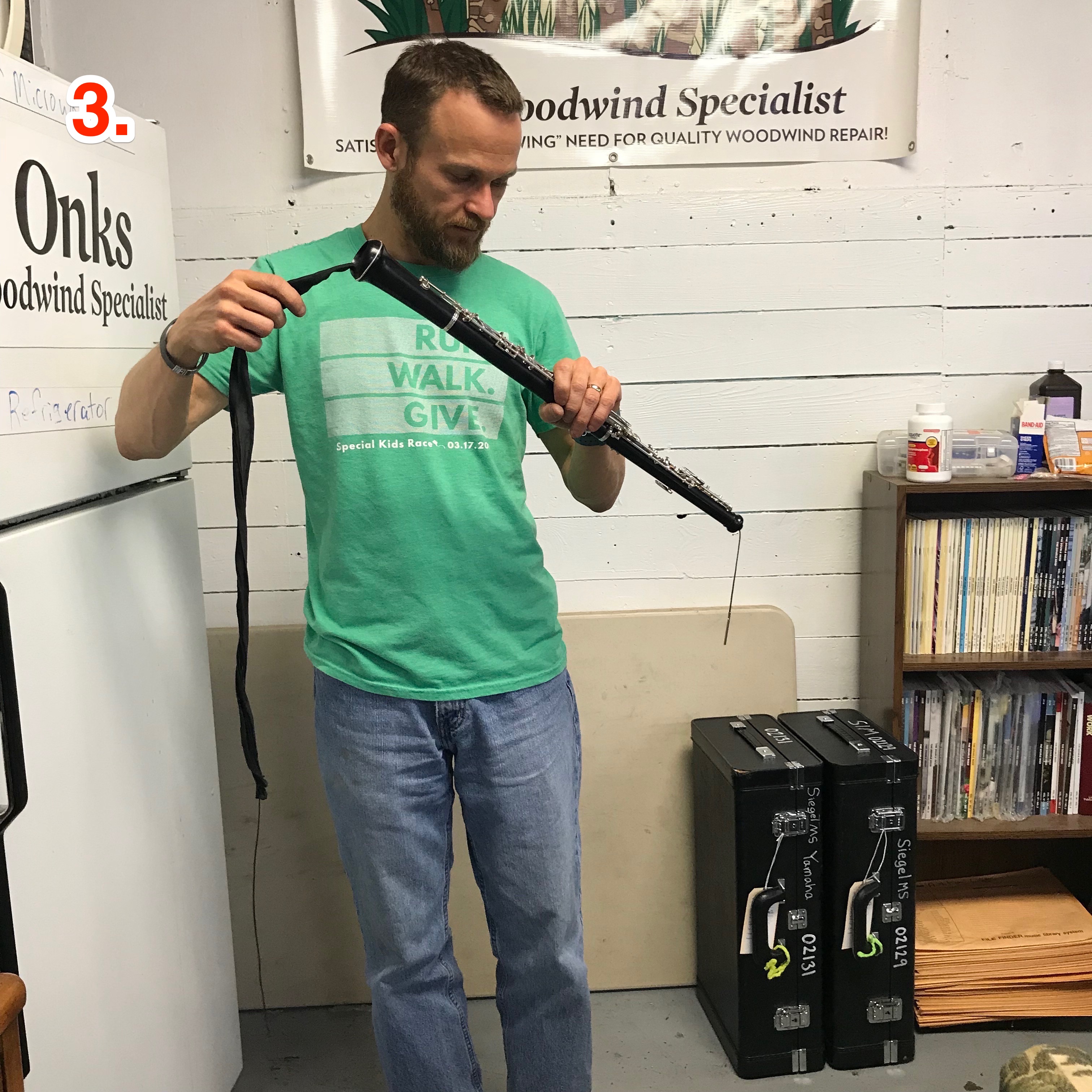

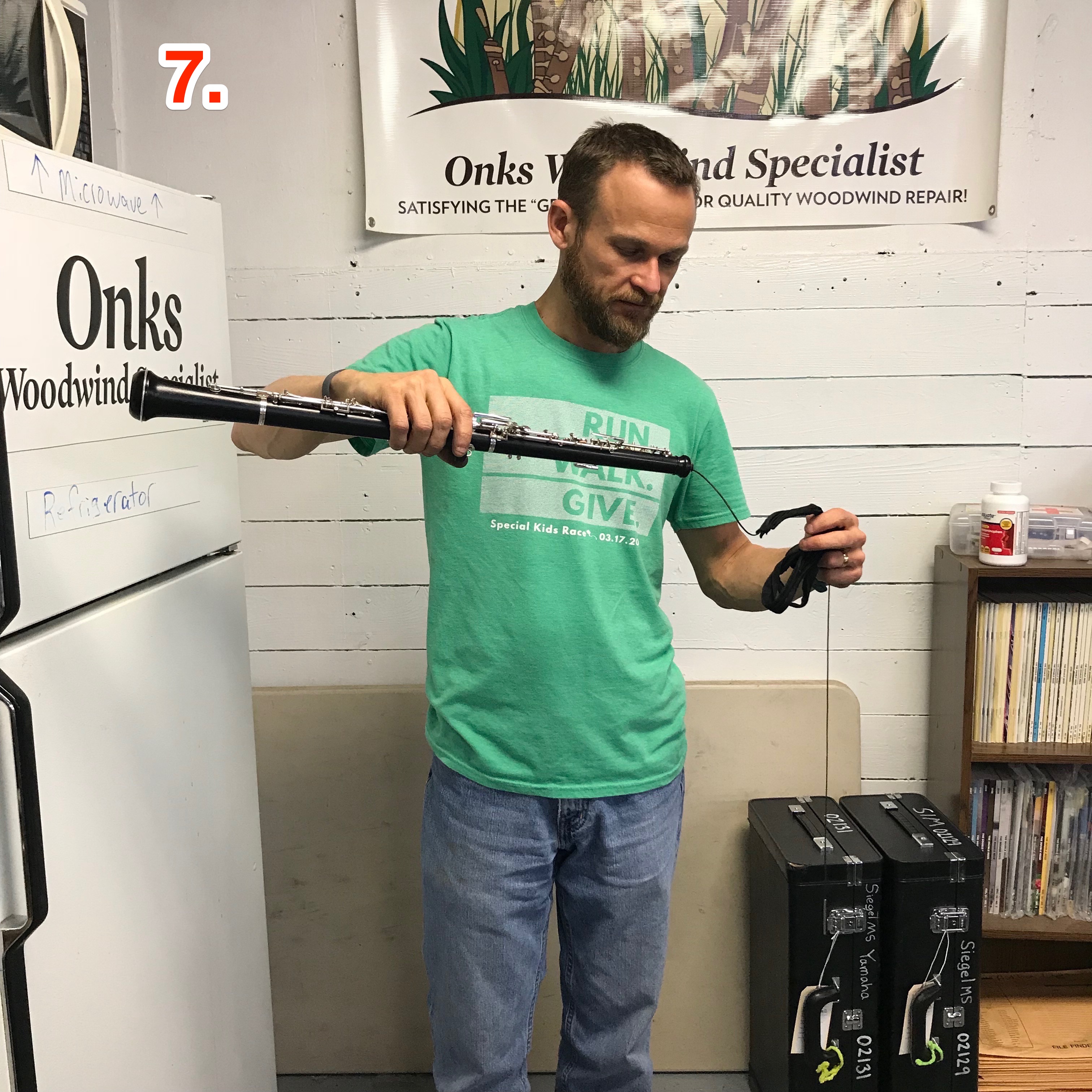

- Completely disassemble instrument so we can remove all springs.

- Clean all posts, rods and hinge tubes so we can fit keys.

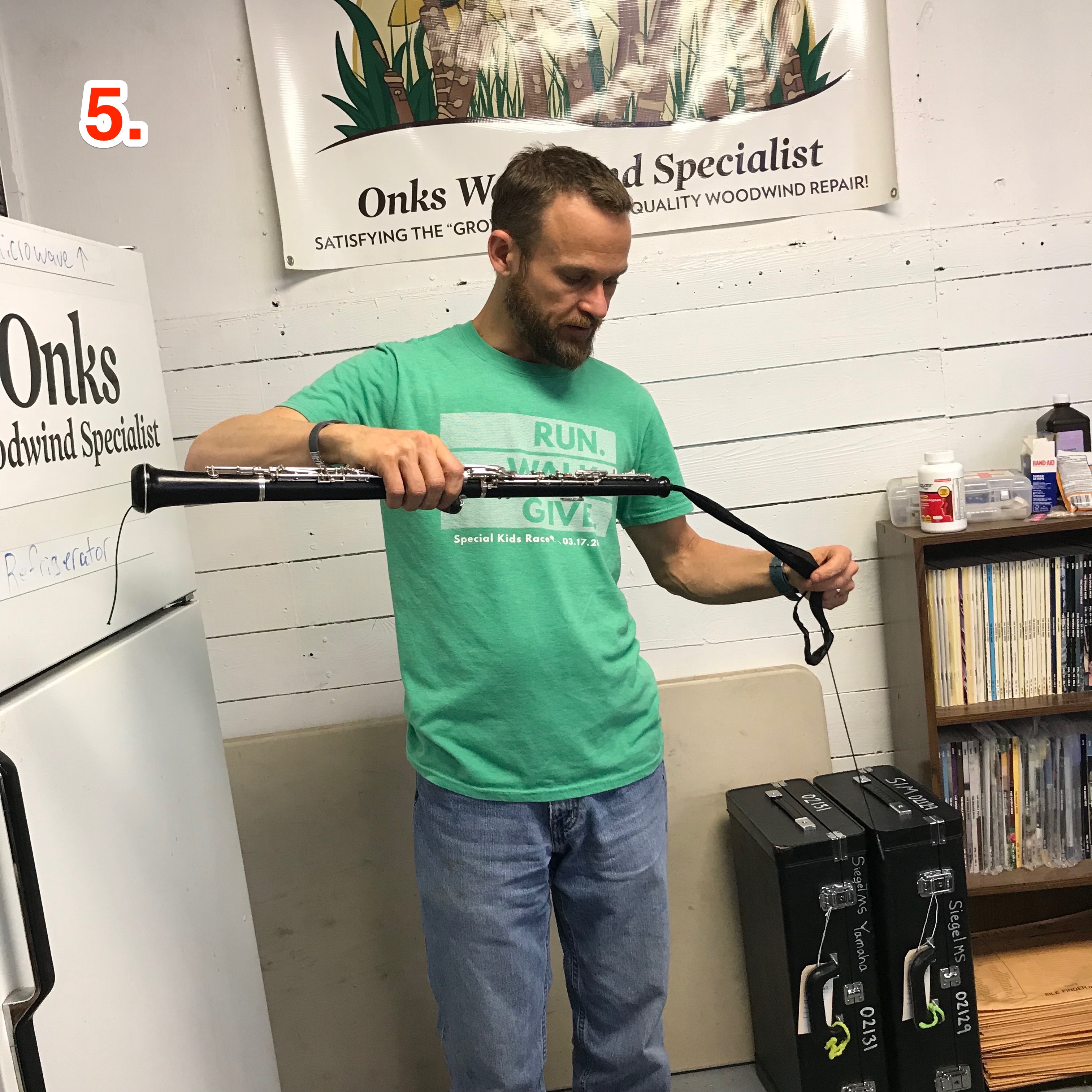

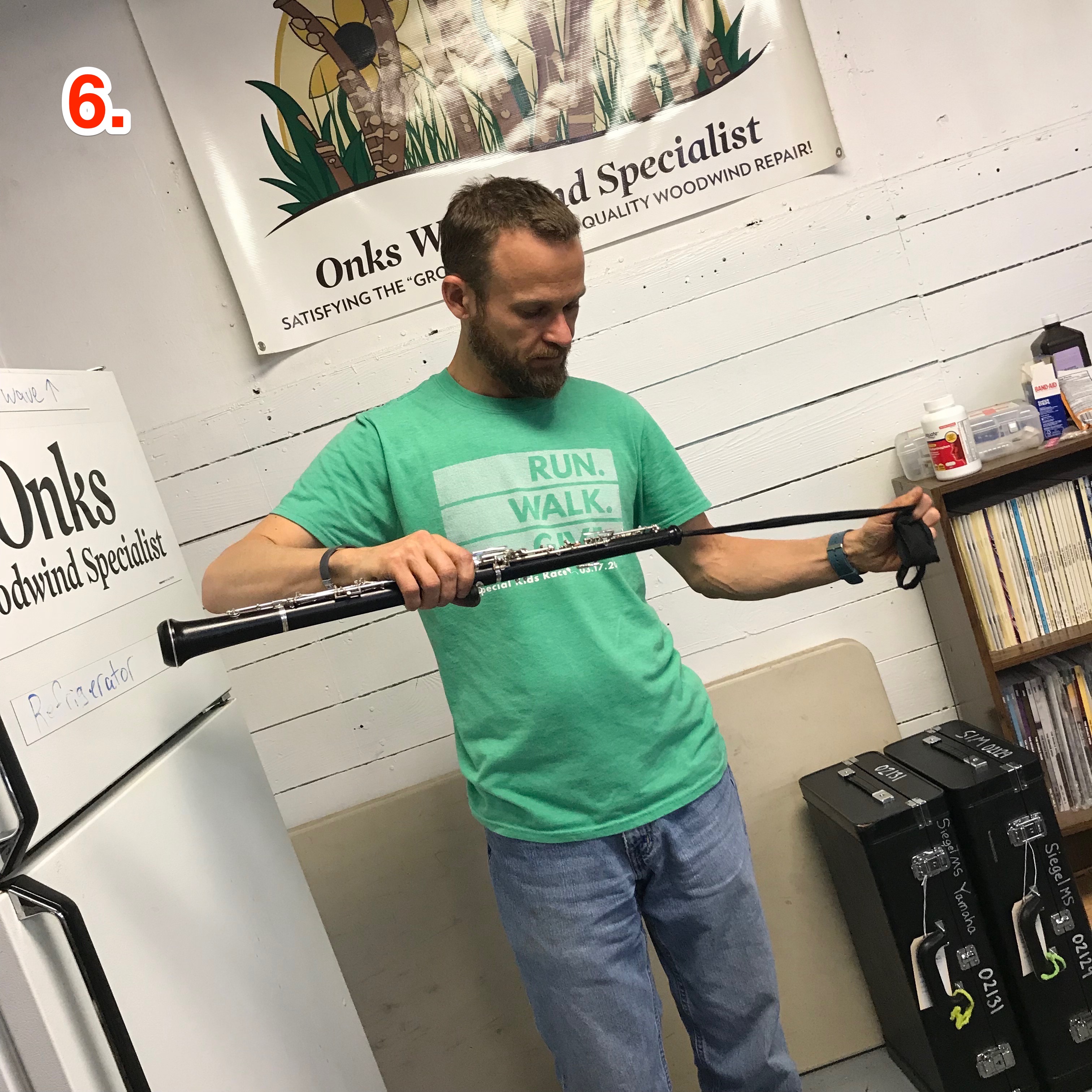

- Mechanically fit all keys on the instrument individually.

- Fitting keys involves swaging keys tighter onto the rods.

- Countersinking pivot screws in posts to fit keys that are on pivots.

- Many times keys/rods are too loose to swag. When this happens we make new oversized rods to stabilize keys.

- Postholes themselves can be too large from years of usage. When this happens we have to rebuild the insides of posts to secure the rod that secures the keys.

- Post threads can sometimes become loose in the instrument. When this happens we must re-secure the post into the instrument.

- Over time braze joints on keys can become weak and split apart. When this happens we must prep and re-braze the key so it will remain stable and not break in the near future.

- Remove all corks from the instrument and keys.

- Remove all pads from pad cups.

- Clean excess glue from all pad cups.

- Secure loose metal tenon rings.

- Ultrasonically clean all keys to prep for buffing.

- Wash instrument body and posts to prep for buffing.

- If plating is intact all posts, keys, metal tenon rings, bell ring, reed well, and metal sockets are buffed to a high shine.

- If plating is not intact keys and posts must be prepped for plating.

- Plating prep includes filing/sanding keys and posts so all surfaces are smooth. Many times this includes building up worn away base metal and sanding down layers of plating to be even with the base metal.

- Once keys have been re-built, all keys and posts are ultrasonically cleaned and buffed to a high shine.

- Keys and posts are ultrasonically cleaned again after buffing, hand inspected to make sure no buffing compound remains and packaged for shipping to the plating company.

- Instrument bodywork. Clean up scratches or previous crack work that need to be touched up.

- Plug all holes in instrument body to confirm body is airtight.

- Polish octave vent wells and octave vents.

- Replace reed well if necessary.

- Rebuild tenon connections if necessary.

- All new tenon corks.

- All new key corks, adjustment, and bumper.

- Re-install posts. (If they were sent off for plating.)

- Re-install springs. (We typically only replace springs when they are broken or do not work properly.)

- Replace all pads during the re-assembly process.

- As one might imagine, pad replacement is a crucial process. Pads have to cover tone holes perfectly, but they must also work in harmony with all other pads. Pad thicknesses are just as important as the pads covering with regards to the mechanisms regulation, pad angles and venting.

All of the procedures above, and more are completed and/or considered while overhauling an oboe or English horn at Onks Woodwind. Overhauls can take between 20 and 30 hours depending on how much the mechanism, keys and body have deteriorated.

We would be honored to bring your oboe or English horn back to life. Whether it is your day to day work horse or family heirloom, Onks Woodwind is here for you. Contact us today!

If you would like to download this information in a printable version, click here.