Post 64: Clogged Tone Holes

We talk about the importance of maintenance around our shop everyday!…

Post 63: Why your oboe is more resistant and resonate after repair.

Over the years, we have had many clients comment that their oboe…

Post 62: How to Insure Your Instrument

Purchasing shipping insurance from your local shipping center…

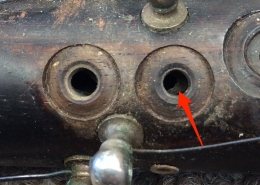

Post 61: Octave vent removal holes must be sealed too…

In previous posts, we have shared with you how to remove, clean…

Post 60: Can the weighted end of your oboe swab damage your oboe?

One of our clients recently asked, "Do you think non-pull through…

Post 59: High Acidic Skin Levels And Your Oboe

We get asked all the time about keeping oboes clean and shiny.…

Post 58: Maintenance starts with your Mouth

We get the opportunity to speak to oboists all the time about…

Post 57: What is a Complete Mechanical Overhaul at Onks Woodwind?

Previously in Post 48 we described why oboe mechanisms are complicated…

Post 56: Why we recommend oiling…

The oboe oiling debate will never cease. I’ve been a member…

Post 55: Swabbing your Oboe by Numbers

Click on the pictures below to view each step individually.

Other…

Post 54: Why do I keep getting water in my octave vents?

Over the years at Onks Woodwind, we have found two reasons that…

Post 53: What does “My oboe keeps going out of adjustment!” mean?

0 Comments

/

We hear clients say this statement all the time, “My oboe keeps…

Post 52: Why your cracked oboe or clarinet doesn’t leak.

During the course of a year, we get many cracked oboes and clarinets…

Post 51: What is your favorite brand of oboe out there today?

I recently had a conversation with an oboist friend of mine from…

Post 50: How to win a major oboe and/or clarinet audition!

There was a guy that I heard about a while back that was known…

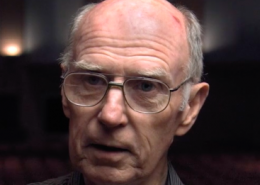

Post 49: Dr. Dan Ross

Recently Arkansas State University produced the video below about…

Post 48: What is an annual cleaning/set-up at Onks Woodwind?

"The mechanisms of an oboe and English horn are so complicated!"…

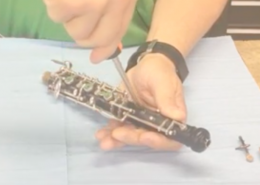

Post 47: Remove, Clean and Re-install Oboe Octave Vents

Here in the professional oboe repair shop, we are frequently…

https://www.onksws.com/wp-content/uploads/2017/04/Screen-Shot-2018-09-19-at-8.32.59-PM.png

312

333

Jason Onks

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

Jason Onks2017-04-29 06:53:422018-09-19 20:33:57Post 46: Definition of #Onksd

https://www.onksws.com/wp-content/uploads/2017/04/Screen-Shot-2018-09-19-at-8.32.59-PM.png

312

333

Jason Onks

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

Jason Onks2017-04-29 06:53:422018-09-19 20:33:57Post 46: Definition of #Onksd

Post 45: Young Harris Clarinet Summit, April 1 2017

Here at Onks Woodwind Specialists, we love educating our clients…

Post 44: Overnight Success

After visiting the Laubin oboe shop in Peekskill NY, Jason is…

Post 43: Contras and Basses can put you through your paces…

Have you ever been frustrated trying to play your bass clarinet?…

Post 42: From Humble Beginnings…

Ten years ago today, I took a huge leap into the world of self…

Post 41: Meeting Tom Hiniker

Onks Woodwind went on the road. Jason and Keith took an educational…

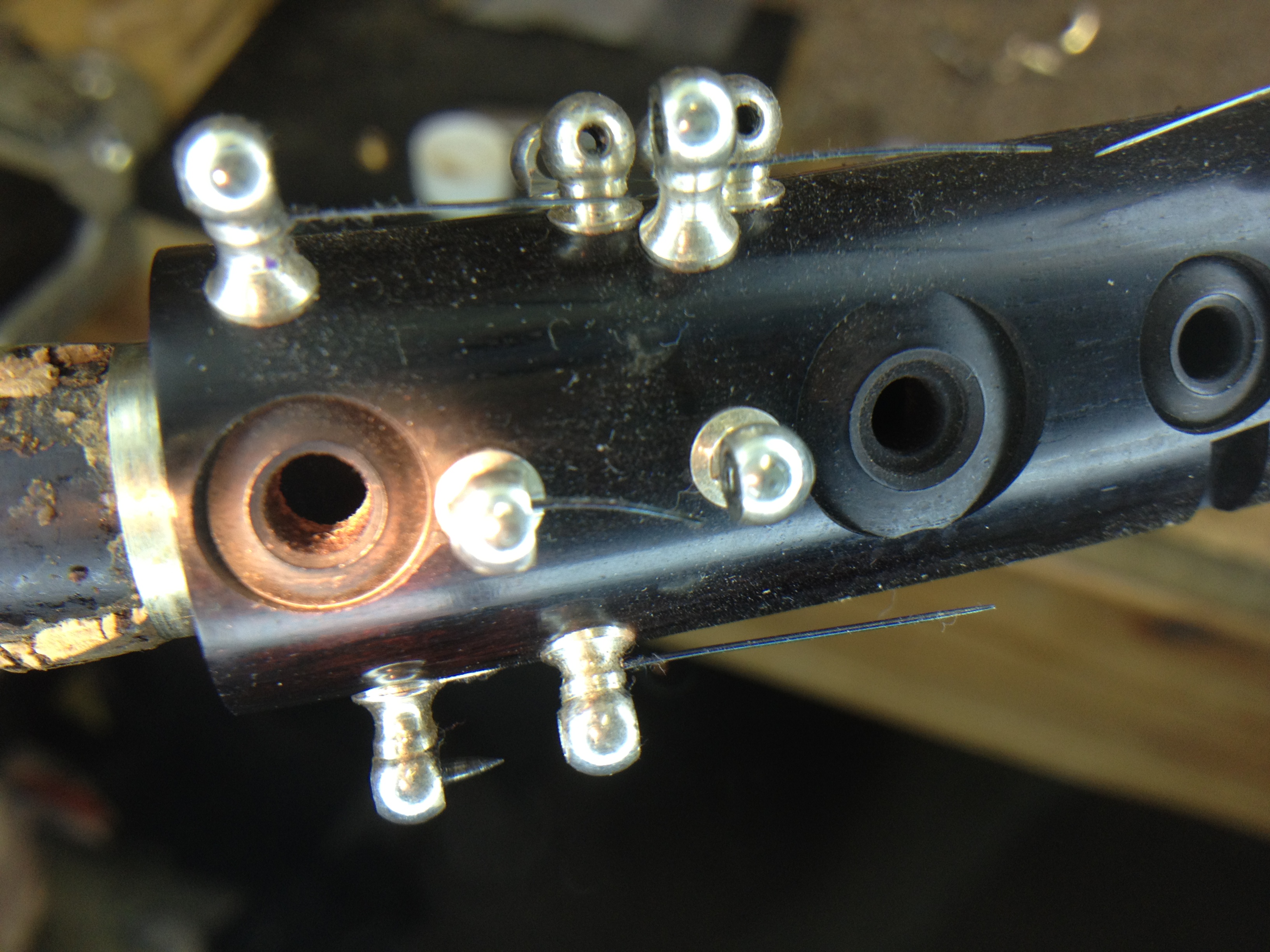

Post 40: Visual: Why Annual Cleanings are So Important

Below is a picture showing why annual cleanings on your instrument…

Post 39: Proper Oboe Assembly

In this video we describe the way we recommend you assemble an…

Post 38: Speaking with TN Governor’s School’s Oboe Studio

This week Jason had the opportunity to speak…

Post 37: Another Laubin Oboe Overhaul Out the Door!

This overhaul included:

complete mechanical fitting and tightening…

Post 36: Half-Hole Finger Plate Upgrade

Wanted to share with you this unusual repair we recently completed…

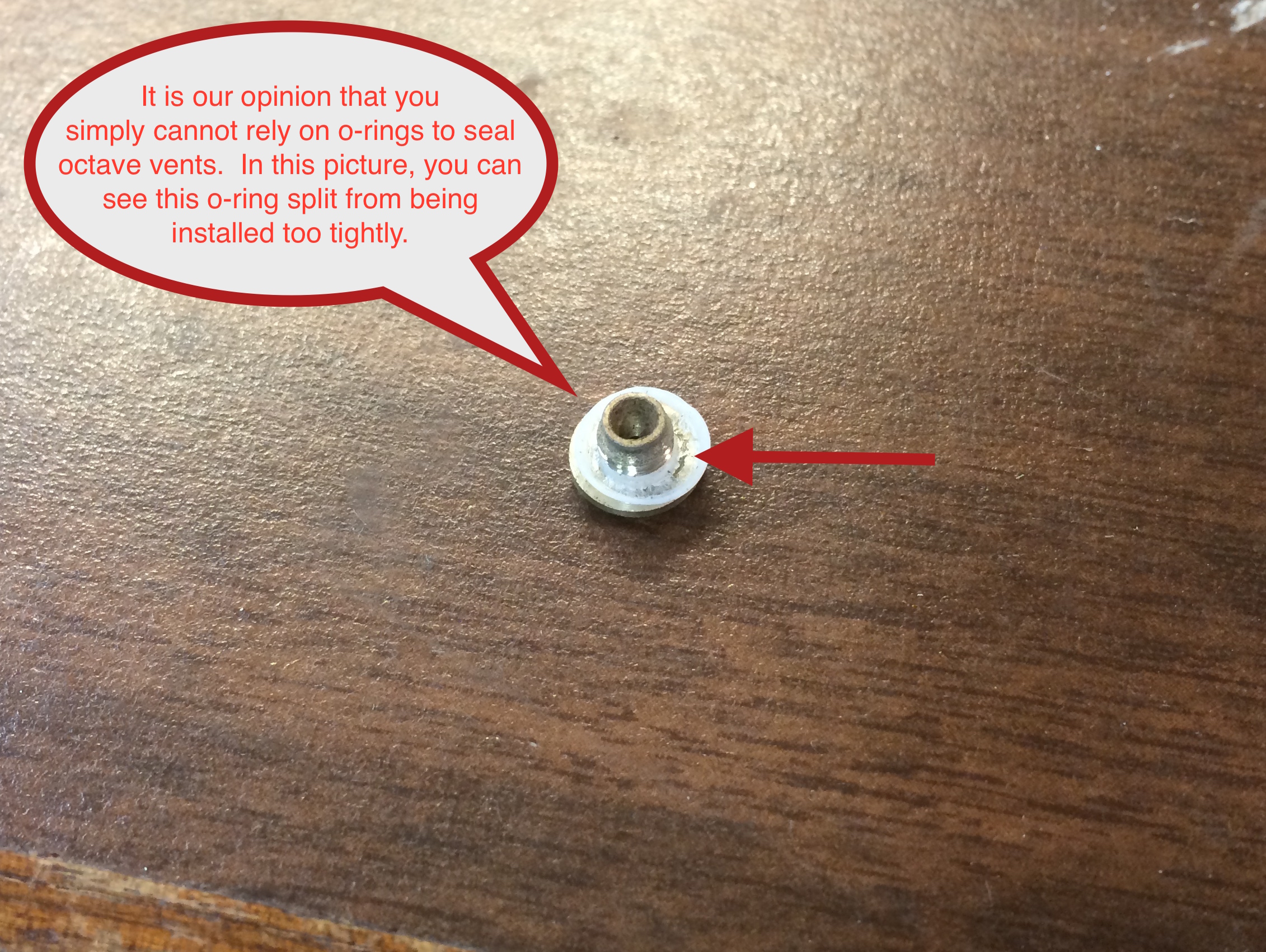

Post 35: How to seal your oboe octave vents

In our previous blog post 33, Should you seal octave vents? we…

Post 34: Troy University Clarinet Day 3/28/15

On Saturday, March 28th, I had the honor of attending Troy University’s…

Post 33: Should You Seal Octave Vents?

Through the years I have heard many conversations and have been…

Post 32: UNLV, Bocal Majority Camp a Success!

I'm finally able to update you on my trip to Las Vegas! Over…

Post 31: The Oboe Reed Is Not A Tuning Slide, by Jared Hauser

Jared Hauser describes why oboists should not pull their reed…

Post 30: Guest-Dr. Todd Waldecker, Clarinet Professor MTSU

Have you ever wondered how much clarinet mouthpiece you should…

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

0

0

Jason Onks

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

Jason Onks2014-03-24 18:07:182020-05-10 13:24:59Post 29: Guest Interview-Myles Harlan

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

0

0

Jason Onks

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

Jason Onks2014-03-24 18:07:182020-05-10 13:24:59Post 29: Guest Interview-Myles Harlan

Post 28: Selmer Alto Clarinet

Jonathan had the pleasure of overhauling a Selmer Paris Alto…

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

0

0

Jason Onks

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

Jason Onks2014-03-20 08:51:172020-05-10 13:27:08Post 27: Clarinet F/C-E/B Relationship

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

0

0

Jason Onks

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

Jason Onks2014-03-20 08:51:172020-05-10 13:27:08Post 27: Clarinet F/C-E/B Relationship

Post 26: Guest-Larry Mueller

Larry Mueller briefly shares some great tips for beginning o…

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

0

0

Jason Onks

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

Jason Onks2014-03-14 17:55:272020-05-10 13:30:40Post 25: How To Swab Your Oboe

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

0

0

Jason Onks

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

Jason Onks2014-03-14 17:55:272020-05-10 13:30:40Post 25: How To Swab Your Oboe https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

0

0

Jason Onks

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

Jason Onks2014-03-11 21:25:402020-05-10 13:33:18Post 24: How to Apply Cork Grease

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

0

0

Jason Onks

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

Jason Onks2014-03-11 21:25:402020-05-10 13:33:18Post 24: How to Apply Cork Grease https://www.onksws.com/wp-content/uploads/2014/01/Cold-Winter-Weather-Safety-Tips-A195839884-e1589135808517.jpeg

1001

1001

Jason Onks

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

Jason Onks2014-01-28 20:22:162020-05-10 13:37:05Post 23: Cold Weather

https://www.onksws.com/wp-content/uploads/2014/01/Cold-Winter-Weather-Safety-Tips-A195839884-e1589135808517.jpeg

1001

1001

Jason Onks

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

Jason Onks2014-01-28 20:22:162020-05-10 13:37:05Post 23: Cold Weather https://www.onksws.com/wp-content/uploads/2014/01/Screen-Shot-2020-05-10-at-1.40.03-PM-e1589136085361.png

214

214

Jason Onks

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

Jason Onks2014-01-18 17:25:242020-05-10 13:41:35Post 22: Dirty/Clean Oboe

https://www.onksws.com/wp-content/uploads/2014/01/Screen-Shot-2020-05-10-at-1.40.03-PM-e1589136085361.png

214

214

Jason Onks

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

Jason Onks2014-01-18 17:25:242020-05-10 13:41:35Post 22: Dirty/Clean Oboe

Post 21: When Instruments Can Talk….

Here at Onks Woodwind, we frequently say, "It would be nice if…

Post 20: “Saxophone Lung”

Here at Onks Woodwind we always recommend an annual cleaning. …

Post 19: Leblanc “Paperclip” Contra

Recently Jonathan had the opportunity to repair a "paperclip"…

Post 18: Yet another example of why you need a yearly cleaning!

We received the oboe below for a cleaning and set-up this week. …

Post 17: Shipping, what not to do!

I received this box the other day. The box was crushed in on…

Post 16: How much cork grease do I really need?

We receive clarinets and oboes here at Onks Woodwind all the…

Post 15: Oboe Adjustment? or Cleaning?

When it comes to maintaining your oboe, there are a couple of…

Post 14: Cool Repair!

We received this clarinet where the left hand levers thread saddle…

Post 13: Soaking Oboe Reeds

To get the most out of your oboe reed you should always soak…

Post 12: Complete Mechanical Overhaul with Key and Post Plating

This oboe is a very old Loree that I was able to bring back to…

Post 11: World Premier by Nashville’s very own Roger Wiesmeyer!

World Premiere of John Marvin Work in ALIAS Winter Concert

ALIAS…

Post 10: Cold Weather Warning!

During the winter months, your oboe/clarinet will get cold.…

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

0

0

Jason Onks

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

Jason Onks2012-12-29 07:41:262020-05-07 07:45:06Post 9: Anything is Possible!

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

0

0

Jason Onks

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

Jason Onks2012-12-29 07:41:262020-05-07 07:45:06Post 9: Anything is Possible! https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

0

0

Jason Onks

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

Jason Onks2012-10-20 11:41:172020-05-06 19:36:54Post 8: Laubin’s Legacy: Making Music

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

0

0

Jason Onks

https://www.onksws.com/wp-content/uploads/2018/08/Onks-Woodwind-Logo-300x125.png

Jason Onks2012-10-20 11:41:172020-05-06 19:36:54Post 8: Laubin’s Legacy: Making Music

Post 7: Crack Prevention

Wood oboes slowly expand and contract constantly throughout the…

Post 6: Customer Service!

There is a lot of talk out there about customer service. When…

Post 5: Clarinet Mouthpiece Swab?

I received a clarinet in for repair today, nothing unusual. …

Post 4: Maintain on a Yearly Basis, Part 2

In my previous post, Maintain on a Yearly Basis, I described…

Post 3: Maintain on a Yearly Basis

Maintenance is a part of our life. No matter how you look at…

Post 2: Sticky 1st Octave Pad

There are many reasons your 1st octave pad could be sticking.…

Post 1: Be careful of your low B and Bb levers.

When laying your oboe down be careful not to lay it on the left-hand…